The Ultimate Guide to Thermal Printers: Everything You Need to Know

1. Introduction to Thermal Printers

What Are Thermal Printers?

Thermal printers are specialized devices that use heat to produce images or text on paper. Unlike traditional inkjet or laser printers, thermal printers eliminate the need for ink cartridges or toner, relying instead on a thermal print head to apply heat to specially coated paper. This heat triggers a chemical reaction, causing the paper to change color—typically to black—resulting in crisp, clear prints. This innovative technology makes thermal printers a go-to solution for businesses prioritizing speed, reliability, and low maintenance.

Why Thermal Printers Matter Today

The popularity of thermal printers has surged across various industries due to their efficiency and versatility. You’ll find them in retail stores printing receipts, in warehouses generating shipping labels, and in hospitals creating patient wristbands. Their ability to handle high-volume printing tasks with minimal downtime has made them indispensable in fast-paced environments. For instance, a busy checkout line relies on the rapid output of thermal receipt printers to keep transactions smooth and customers satisfied.

Market Growth and Future Trends

According to industry projections, the thermal printing market is set to reach $53.5 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.4%. This expansion is fueled by the rising demand for cost-effective printing solutions in sectors like e-commerce, healthcare, and logistics. As businesses continue to seek ways to optimize operations, thermal printers stand out as a reliable choice. To learn more about their impact, explore our Ultimate Guide to Thermal Printers.

Whether you’re a small business owner or part of a large enterprise, understanding thermal printers can help you make informed decisions about your printing needs. This guide will walk you through everything from their mechanics to their applications, ensuring you have all the information you need.

2. How Thermal Printers Work

The Core Mechanism: Heat-Based Printing

At the heart of every thermal printer is a simple yet ingenious principle: heat. The thermal print head, equipped with numerous tiny heating elements, is the key component. When an electrical current passes through these elements, they heat up selectively, transferring heat to the paper or a ribbon to create the desired image or text. This process happens in milliseconds, allowing thermal printers to produce prints at remarkable speeds.

Direct Thermal Printing Explained

In direct thermal printing, the print head applies heat directly to heat-sensitive paper. This paper is coated with a chemical layer that reacts to heat by turning black (or another color in rare cases). The result is a fast, efficient printing method with no need for ink or ribbons. Direct thermal printing is widely used for short-term applications like receipts and tickets, where durability isn’t a primary concern. Curious about its applications? Check out our post on 10 Essential Applications of Thermal Printers.

Thermal Transfer Printing Unveiled

Thermal transfer printing, on the other hand, uses a ribbon coated with wax or resin-based ink. The print head heats the ribbon, melting the ink and transferring it onto the paper or other materials like plastic or fabric. This method produces more durable prints, making it ideal for labels that must endure harsh conditions, such as outdoor exposure or chemical contact. It’s a preferred choice for barcode labels and asset tracking in industries like manufacturing.

Both methods showcase the versatility of thermal printing technology. For a deeper technical breakdown, visit our Guide to Receipt and Label Printing Technologies.

3. Types of Thermal Printers: Direct Thermal vs. Thermal Transfer

Direct Thermal Printers: Simplicity in Action

Direct thermal printers are straightforward in design and operation. They rely on heat-sensitive paper that darkens when heated by the print head. This eliminates the need for ink, toner, or ribbons, simplifying the printing process. These printers are compact, cost-effective, and perfect for applications where prints don’t need to last long, such as retail receipts or event tickets. However, their prints can fade when exposed to heat, light, or chemicals over time.

Thermal Transfer Printers: Durability Defined

Thermal transfer printers take durability to the next level. By using a ribbon to transfer ink onto the printing surface, they create long-lasting prints that resist fading and withstand tough environments. This makes them ideal for applications like product labeling in warehouses or outdoor signage. While they require ribbons—adding to the cost—their ability to print on diverse materials like polyester or vinyl sets them apart. Explore our Guide to Barcode Label Printers for more insights.

Key Differences and Choosing the Right Type

The choice between direct thermal and thermal transfer depends on your needs. Direct thermal printers offer lower operating costs and simplicity, while thermal transfer printers provide superior durability and versatility. For a side-by-side comparison, see our blog post on Thermal Printers vs. Inkjet Printers, which also touches on these distinctions.

Both types have unique strengths, making them suited to different tasks. Understanding these differences ensures you select the best printer for your specific application.

4. Advantages and Disadvantages of Thermal Printers

Advantages of Thermal Printers

Thermal printers come with a host of benefits that make them a top choice for many businesses:

- Speed: They excel in high-volume settings, printing receipts or labels in seconds.

- Low Maintenance: With fewer moving parts and no ink to replace, upkeep is minimal.

- Cost-Effective: Over time, the absence of consumables like ink reduces expenses.

- Quiet Operation: They produce little noise, ideal for customer-facing environments.

These advantages make thermal printers a staple in retail and logistics. As industry expert Jane Smith from PrintTech Solutions notes,

“Thermal printers deliver unmatched efficiency, making them the backbone of modern point-of-sale systems.”

Disadvantages to Consider

Despite their strengths, thermal printers have limitations:

- Limited Color Options: Most are monochrome, with color printing being rare and costly.

- Print Durability: Direct thermal prints fade over time; thermal transfer is better but not infallible.

- Paper Sensitivity: Thermal paper can degrade under certain environmental conditions.

For a detailed look at these challenges, read our article on Thermal Printer Disadvantages.

Weighing the Pros and Cons

Thermal printers strike a balance between efficiency and practicality, though they’re not perfect for every scenario. Businesses must weigh these factors against their specific needs—speed and cost savings versus color needs or print longevity. Our Guide to Choosing the Right Thermal Printer can help you decide.

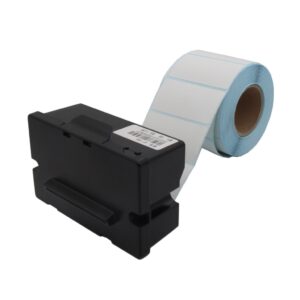

Featured Thermal Printers

Label Printer

Kiosk Printer

POS Printer

Printer Mechanism

8. Maintenance and Care for Thermal Printers

Regular Cleaning for Optimal Performance

To keep your thermal printer running smoothly, regular cleaning is essential. Dust, debris, and adhesive residue from labels can accumulate on the printhead, leading to poor print quality or even damage. Use a lint-free cloth and isopropyl alcohol to gently clean the printhead every few weeks, or more often in dusty environments. Always power off and unplug the printer before cleaning to ensure safety.

Replacing Consumables: Paper and Ribbons

Thermal printers rely on consumables like thermal paper or ribbons (for thermal transfer models). Monitor usage and replace them promptly to avoid interruptions. For direct thermal printers, use high-quality thermal paper to prevent wear on the printhead. In thermal transfer printers, ensure the ribbon matches the printer’s specifications—mismatched ribbons can cause smudging or incomplete prints. Check our Guide to Thermal Printer Maintenance for more tips.

Troubleshooting Common Issues

Even with proper care, issues like paper jams or faded prints may arise. For jams, carefully remove the stuck paper without forcing it, and inspect the paper path for obstructions. Faded prints often indicate a dirty printhead or low-quality media—clean the head and test with recommended paper or ribbons. If problems persist, consult the printer’s manual or contact support. Our Step-by-Step Troubleshooting Guide can help resolve these quickly.

Extending Printer Lifespan

Proactive maintenance extends the life of your thermal printer. Store it in a cool, dry place away from direct sunlight, as heat can degrade components. Avoid overworking the printer beyond its duty cycle, and schedule professional servicing annually for heavy-use models. These steps minimize downtime and repair costs, ensuring consistent performance for years.

Proper care transforms your thermal printer into a long-term investment. For detailed maintenance schedules, explore our Comprehensive Guide to Thermal Printers.

9. Market Overview of Thermal Printers

Current Trends in Thermal Printing

The thermal printer market is evolving rapidly, driven by e-commerce and contactless technology. In 2024, demand for portable and wireless thermal printers has surged, reflecting the need for flexibility in retail and logistics. Sustainability is another trend, with manufacturers developing eco-friendly thermal paper and energy-efficient models to meet green standards.

Key Players in the Industry

Brands like Zebra Technologies, Brother, and Epson dominate the thermal printer market, offering a range of models from desktop to industrial-grade. Zebra excels in rugged, high-volume printers for logistics, while Brother focuses on compact, user-friendly options for small businesses. Epson blends innovation with reliability, popular in retail and healthcare. These companies continually innovate to stay competitive.

Growth Projections and Opportunities

Analysts predict steady growth in the thermal printer market through 2030, fueled by automation and the expansion of global supply chains. The rise of smart labels with RFID integration is a key opportunity, particularly in logistics and healthcare. Small businesses also benefit, as affordable desktop models make thermal printing accessible. Learn more about market trends in our Applications of Thermal Printers post.

Challenges Facing the Market

Despite growth, challenges persist. Competition from inkjet and laser technologies pressures thermal printer manufacturers to keep costs low. Supply chain disruptions, like shortages of thermal paper, also impact availability. Addressing these requires innovation and resilience from industry leaders.

The thermal printer market is dynamic, balancing opportunity and competition. Staying informed helps businesses leverage this technology effectively.

10. Frequently Asked Questions

What is the difference between direct thermal and thermal transfer?

Direct thermal printers use heat-sensitive paper that darkens when heated, ideal for short-term prints like receipts. Thermal transfer printers use a ribbon to transfer ink onto various materials, producing durable labels for long-term use. Each suits different applications—see our Comparison Guide for details.

How long do thermal prints last?

Direct thermal prints typically last 6-12 months before fading, depending on exposure to light or heat. Thermal transfer prints can last years, even decades, if stored properly, making them better for archival purposes.

Are thermal printers expensive to maintain?

No, thermal printers are generally low-maintenance, requiring no ink or toner. Costs arise from thermal paper or ribbons, but regular cleaning keeps repairs minimal. Check our Cost Guide for a breakdown.

Can thermal printers print in color?

Standard thermal printers are monochrome, but dye-sublimation thermal printers can print vibrant colors, often used for photos. Explore this in our Mini Photo Printer Guide.

Conclusion

Thermal printers are a cornerstone of modern business, offering speed, reliability, and cost-efficiency across industries like retail, logistics, and healthcare. From understanding their types—direct thermal and thermal transfer—to choosing the right model and maintaining it, this guide has covered it all. While they excel in specific applications, alternatives like inkjet or laser printers may suit other needs. As the market grows, thermal printers continue to adapt, meeting demands for portability and sustainability.

Ready to invest in a thermal printer? Start with our Comprehensive Guide. For further reading, visit external resources like Zebra Technologies or Epson’s Thermal Printer Line.