Introduction:potential of thermal printer color

As an expert in the field of thermal printing, I have witnessed firsthand the evolution of this technology from its traditional monochrome roots to the exciting possibilities of color printing. Thermal printers have long been celebrated for their speed, efficiency, and reliability, primarily used for printing receipts, labels, and barcodes in black and white. However, as industries evolve and the demand for vibrant color outputs increases, the question arises: can thermal printers print in color? In this article, I will explore the capabilities of color thermal printing, its applications across various sectors, and the advantages and limitations associated with this technology.According to recent market research, the global thermal printing market exceeded $30 billion in 2019 and is expected to grow at a compound annual growth rate (CAGR) of 7% by 2026. This growth reflects a burgeoning interest in color thermal printing solutions across diverse sectors.

What is a Color Thermal Printer?

The Technology Behind Thermal Printers

To understand color thermal printers, it’s essential to grasp how thermal printing technology works. There are two primary methods used in thermal printing: direct thermal printing and thermal transfer printing.

Direct Thermal Printing

Direct thermal printing is a straightforward process where heat is applied directly to heat-sensitive paper. When the print head heats specific areas of the paper, it creates a chemical reaction that produces an image. This method is efficient for monochrome printing but has limitations when it comes to color output.

Thermal Transfer Printing

On the other hand, thermal transfer printing utilizes a ribbon coated with wax or resin-based ink. The print head applies heat to the ribbon, melting the ink onto the label material underneath. This technology allows for more vibrant colors and higher-quality prints compared to direct thermal printing. By using different colored ribbons (cyan, magenta, yellow, and black—CMYK), thermal transfer printers can produce full-color images suitable for various applications.

Differences Between Monochrome and Color Thermal Printing

When comparing monochrome and color thermal printing, several factors come into play:

| Feature | Monochrome Thermal Printing | Color Thermal Printing |

|---|---|---|

| Color Capability | Black and White | Basic colors (via thermal transfer) |

| Speed | Faster | Slower due to multiple ribbon passes |

| Cost | Lower | Higher due to consumables |

| Applications | Receipts, simple labels | Color-coded labels, branding |

| Durability | Moderate | Higher with thermal transfer |

Understanding these differences is crucial for businesses considering which type of printer best suits their needs.

Applications of Color Thermal Printing

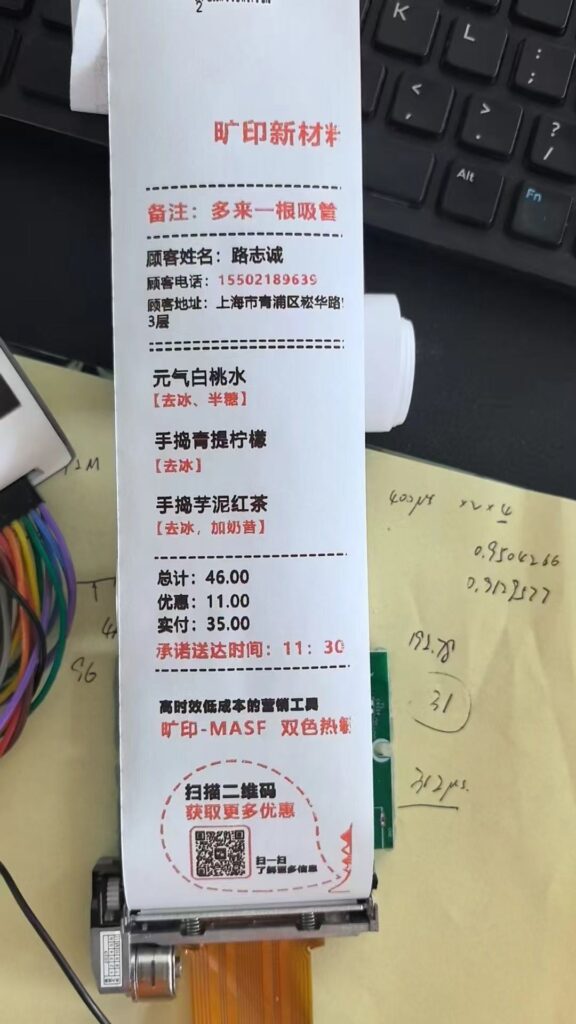

Retail and Branding

In retail environments, color-coded receipts and branded labels can significantly enhance customer experience and brand recognition. For example, boutique stores may use vibrant labels that reflect their brand identity while café chains can print colorful promotional materials that attract customers’ attention. Imagine walking into a café where every receipt not only serves its functional purpose but also reinforces the brand’s image through thoughtful design and color use.

Logistics and Warehousing

In logistics and warehousing, color-coded shipping labels simplify inventory management by allowing workers to quickly identify items based on color indicators. For instance, using red labels for urgent shipments and green for standard deliveries helps improve efficiency in busy logistics operations. This visual cue reduces errors and speeds up processing times—an invaluable asset in fast-paced environments.

Healthcare

In healthcare settings, medical labels with color-coded warnings play a crucial role in patient safety. For example, using bright colors on medication labels helps prevent mix-ups between similar-looking drugs. A hospital that employs color-coded labels can significantly reduce the risk of medication errors—a critical factor when it comes to patient care.

Food and Beverage

Color labeling is essential in the food industry for compliance with safety standards. Expiration dates printed in bright colors alert staff to product freshness at a glance—helping reduce waste while ensuring consumer safety. Imagine a grocery store where employees can quickly identify expired products thanks to clear visual indicators; this not only enhances safety but also improves customer trust.

Manufacturing

In manufacturing environments, process labels featuring color codes can simplify assembly line workflows by providing clear instructions or warnings associated with specific tasks or equipment. This clarity enhances efficiency and helps maintain safety standards on the production floor.

Advantages of Color Thermal Printers

Enhanced Visual Communication

One of the most significant advantages of color thermal printing is enhanced visual communication. Color improves readability and allows for faster identification of important information through visual cues. This enhancement can lead to better decision-making processes among employees who rely on quick access to critical data.

Versatility Across Industries

Modern color thermal printers are compatible with various materials including synthetic labels and black mark paper. This versatility enables businesses to choose the best media for their specific applications without compromising quality or performance.

Long-Lasting and Durable Prints

With resin-based ribbons used in many color thermal printers, users benefit from durable prints that withstand harsh environments—making them ideal for outdoor labeling or industrial applications. These prints are designed to resist fading over time, ensuring that important information remains legible even under challenging conditions.

Environmental Initiatives

As sustainability becomes increasingly important across industries, many manufacturers are introducing eco-friendly materials like BPA-free paper. These initiatives help reduce environmental impact while maintaining high-quality results from printer setups.

Limitations of Color Thermal Printing

Cost Implications

One of the primary drawbacks of color thermal printers is their higher upfront investment compared to standard monochrome models. The additional costs stem from specialized printheads, ribbon mechanisms, and higher-priced consumables such as ribbons and color-compatible papers.

Limited Color Range

While advancements have been made in color thermal printing technology, there remains a limitation in terms of the range of colors available compared to full-spectrum printers like inkjet or laser models. Most thermal transfer printers typically produce basic colors which may not meet all branding needs.

Maintenance and Consumables

Color thermal printers often require specialized paper and ribbons that add to operational costs over time. Additionally, maintenance requirements may increase due to the more complex printing process involved in producing multicolor outputs.

Slower Printing Speeds

Color printing often requires more complex processes than monochrome printing due to multicolor ribbon usage. As a result, users may experience slower print speeds when producing multi-colored outputs compared to standard black-and-white prints.

Comparing Thermal Printers with Other Technologies

Thermal Printers vs. Inkjet Printers

When comparing thermal printers with inkjet printers:

- Pros:

- Thermal Printers: Faster print speeds; lower maintenance costs; no need for ink cartridges.

- Inkjet Printers: Superior quality for full-color images; broader spectrum of colors available.

- Cons:

- Thermal Printers: Limited color options; potential fading issues.

- Inkjet Printers: Slower speeds; higher operational costs due to ink replacement.

Thermal Printers vs. Laser Printers

In comparing thermal printers with laser printers:

- Pros:

- Thermal Printers: Compact designs; ideal for label production.

- Laser Printers: High-quality text output; faster speeds for large documents.

- Cons:

- Thermal Printers: Limited color capabilities; specialized media required.

- Laser Printers: Larger footprint; higher energy consumption during operation.

Cost Comparison

When evaluating cost considerations:

- Thermal Printers: Generally lower operational costs due to no need for ink but may incur higher consumable costs for ribbons.

- Inkjet/Laser Printers: Higher initial costs but offer broader capabilities for full-color outputs which may justify expenses depending on business needs.

Market Trends and Statistics

The global market for thermal printers is projected to reach approximately $58.59 billion by 2030. This growth reflects an increasing adoption across various sectors driven by efficiency needs and technological advancements.

Regional Insights

North America continues to be a key player in market growth due to its robust retail sector while Asia-Pacific shows significant potential driven by e-commerce expansion and logistics improvements.

Industry Innovations

The integration of IoT technology into thermal printers allows businesses greater control over their operations through remote monitoring capabilities—enhancing efficiency even further!

Sustainability in Printing

There’s an increasing focus on sustainability within the industry with many manufacturers innovating ways to reduce waste associated with traditional printing methods by exploring alternative materials or processes that minimize environmental footprints overall!

Choosing the Right Color Thermal Printer for Your Needs

When selecting a color thermal printer consider features such as:

- Resolution: Higher DPI ensures sharper images.

- Print Speed: Assess speed based on workload requirements.

- Media Compatibility: Ensure compatibility with different label sizes/materials.

- Connectivity Options: Look for USB/Ethernet/Bluetooth support based on integration needs.

Evaluate investment versus operational benefits by considering long-term savings from reduced consumable costs alongside increased productivity resulting from efficient workflows enabled by your chosen printer model!

Frequently Asked Questions

Can all thermal printers print in color?

No! While some advanced models can produce limited colors using special ribbons most traditional thermal printers are monochrome only!

What industries benefit most from color thermal printers?

Key industries include retail (for branding), logistics (for organization), healthcare (for safety), food & beverage (for compliance), manufacturing (for process labeling)—each utilizing unique advantages provided by this innovative technology!

How much do color thermal printers cost?

Pricing varies widely depending upon features offered but generally ranges anywhere from several hundred dollars up into thousands based upon specifications required operational demands faced within respective environments!

Conclusion

In conclusion,color thermal printers represent an exciting evolution within printing technology offering numerous advantages across various industries! By understanding their capabilities limitations businesses can make informed decisions about how best leverage these innovative solutions enhance operations overall! We encourage readers explore our product line contact us directly consultations tailored specifically towards individual needs!