| Sticker Printer Type | Best For | Print Quality | Cost Range | Long-term Value |

|---|---|---|---|---|

| Thermal Sticker Printer | Shipping labels, barcodes, receipts | Sharp text, basic graphics | $100-500 | Excellent for high-volume |

| Inkjet Sticker Printer | Color stickers, photos, art | Vibrant colors, detailed images | $200-800 | Good for versatility |

| Laser Sticker Printer | Professional labels, waterproof stickers | Durable prints, crisp text | $300-1000 | Best for durability |

What Is a Sticker Printer? A Simple Guide

A sticker printer is a specialized printing device that creates self-adhesive labels and stickers for various applications. Unlike regular printers, these machines are specifically designed to handle adhesive materials and produce durable, professional-quality output that can withstand different environmental conditions.

“Modern sticker printers have evolved from simple label makers into sophisticated business tools that can handle everything from basic shipping labels to complex marketing materials.” – Based on 16 years of industry expertise

The key components of a sticker printer include:

- Print Mechanism: Whether thermal, inkjet, or laser, this determines how your stickers are produced

- Media Handling System: Specially designed to work with adhesive materials

- Control Interface: Allows you to manage print settings and operations

- Connectivity Options: USB, Wi-Fi, or Bluetooth for various printing needs

Sticker printers serve numerous purposes across different industries. In retail, they’re essential for price tags and product labels. In warehouses, they create shipping labels and inventory tags. For marketing teams, they produce promotional stickers and branded materials. Even small businesses and crafters use them for custom packaging and creative projects.

Modern sticker printers offer features like:

- Automatic size detection

- Multiple material compatibility

- Variable print speeds

- Different resolution options

- Auto-cutting capabilities

Choose the Perfect Sticker Printer in 5 Steps

Selecting the right sticker printer requires careful consideration of several key factors. Let’s break down the decision process into manageable steps that will help you make an informed choice.

1. Determine Your Primary Usage

First, analyze your specific printing needs:

- Daily Volume: How many stickers or labels will you print each day?

- Type of Content: Will you primarily print text, barcodes, or full-color images?

- Material Requirements: Do you need weather-resistant or standard labels?

- Size Variations: What sizes of stickers will you typically print?

2. Evaluate Your Budget Comprehensively

Consider all financial aspects:

- Initial Investment: The upfront cost of the printer

- Operating Costs: Materials, ink/ribbon, and maintenance

- Cost per Print: Calculate the average cost for each sticker

- Return on Investment: How quickly will the printer pay for itself?

3. Assess Technical Requirements

Review the technical specifications needed:

- Print Resolution: Higher DPI for detailed graphics

- Print Speed: Pages per minute for your volume needs

- Connectivity Options: USB, network, or wireless capabilities

- Software Compatibility: Works with your existing systems

Types of Sticker Printers: Which One Do You Need?

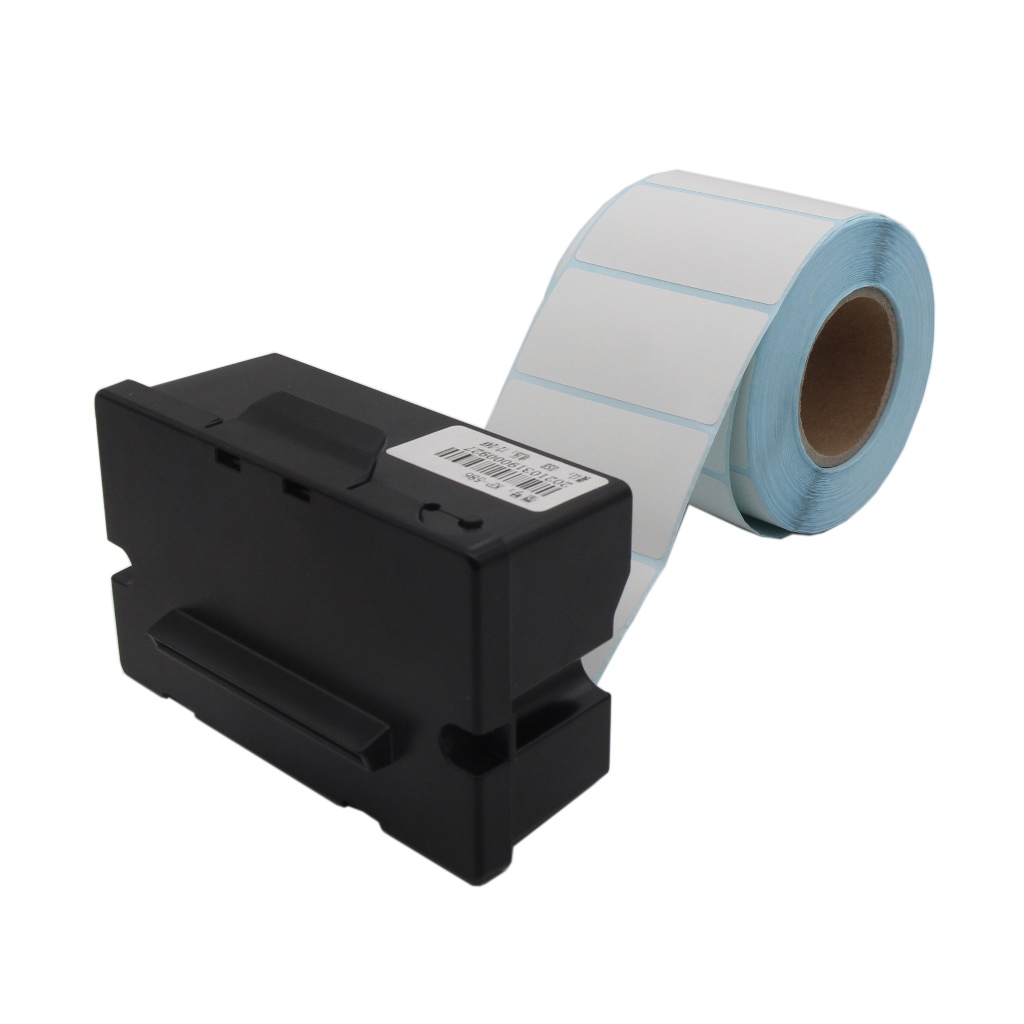

Thermal Sticker Printers

Thermal printers are the workhorses of the label printing industry. These printers use heat to create images on special heat-sensitive materials, making them ideal for:

- High-Volume Applications

- Shipping labels

- Warehouse labels

- Receipt printing

- Barcode labels

Key advantages of thermal printers include:

- No ink or toner required

- Fast printing speeds

- Low maintenance needs

- Reliable performance

- Cost-effective for high volumes

Inkjet Sticker Printers

Inkjet printers excel at producing colorful, high-quality stickers. They’re perfect for:

- Creative Applications

- Product labels

- Marketing materials

- Custom designs

- Photo stickers

Benefits of inkjet sticker printers:

- Excellent color reproduction

- Fine detail capability

- Versatile material options

- Affordable initial cost

- Easy to use

Laser Sticker Printers

Laser printers offer professional-grade quality and durability. They’re best suited for:

- Professional Applications

- Product packaging

- Outdoor labels

- Durable signage

- Professional certificates

Advantages of laser sticker printers:

- Superior text quality

- Water-resistant output

- Fast printing speeds

- Long-lasting results

- Professional finish

Real-World Uses for Sticker Printers

Sticker printers have become essential tools across numerous industries and applications. Understanding these diverse uses can help you maximize the value of your printer investment.

Business Applications

Modern businesses rely on sticker printers for various critical operations:

Retail Operations

- Product Labeling: Price tags, SKU labels, and inventory markers

- Shelf Organization: Category labels and promotional tags

- Security Labels: Warranty stickers and tamper-evident seals

- Seasonal Updates: Sale prices and special offer markers

Warehouse Management

- Inventory Control: Location labels and bin tags

- Shipping Operations: Address labels and tracking codes

- Asset Tracking: Equipment tags and maintenance records

- Safety Information: Warning labels and handling instructions

Manufacturing

- Quality Control: Inspection labels and certification marks

- Component Tracking: Part numbers and serial codes

- Assembly Instructions: Process labels and sequence markers

- Compliance Labels: Safety warnings and regulatory information

Marketing and Branding Applications

Creative professionals use sticker printers to enhance brand visibility:

- Brand Promotion

- Logo stickers for packaging

- promotional giveaways

- Event badges and name tags

- Custom packaging seals

- Product Marketing

- Special edition labels

- Limited time offer stickers

- Product information labels

- QR code stickers for digital engagement

Top Benefits of Modern Sticker Printers

Understanding the advantages of modern sticker printers helps businesses make informed decisions about their investment.

Operational Benefits

- Cost Efficiency

- Reduced waste through on-demand printing

- Lower per-unit costs for small batches

- Minimal storage needs for supplies

- Decreased labor costs for label management

- Time Savings

- Instant label production when needed

- Quick design changes and updates

- Faster order fulfillment

- Reduced waiting time for external suppliers

- Quality Improvements

- Consistent print quality

- Professional appearance

- Durable materials options

- Clear, scannable barcodes

Business Growth Benefits

- Enhanced Brand Image: Professional labels improve product perception

- Market Responsiveness: Quick adaptation to market changes

- Customer Satisfaction: Clear, accurate labeling reduces errors

- Competitive Advantage: Faster turnaround times for custom orders

Expert Tips from Industry Veterans

Drawing from 16 years of experience in thermal printing technology, here are essential tips for maximizing your sticker printer’s performance:

Maintenance Best Practices

- Regular Cleaning

- Clean printheads weekly

- Remove debris and dust daily

- Check and clean rollers monthly

- Maintain clean storage areas

- Material Handling

- Store materials in controlled environments

- Rotate stock to prevent aging

- Check material compatibility

- Test new materials before bulk printing

Optimization Tips

- Print Quality

- Adjust settings for each material type

- Calibrate printer regularly

- Use appropriate print speeds

- Monitor temperature settings

- Cost Management

- Buy supplies in optimal quantities

- Track usage patterns

- Implement waste reduction strategies

- Schedule preventive maintenance

Common Questions & Solutions

Essential Questions About Sticker Printers

Can I use a regular printer to print stickers?

While standard printers can print on sticker paper, they’re not ideal for professional sticker printing because:

- Regular printers lack specialized paper handling mechanisms

- Print durability is significantly lower

- Material options are limited

- Operating costs are typically higher

- Print quality may not meet professional standards

How do I choose the right material for my stickers?

Material selection depends on several key factors:

- Indoor vs. Outdoor Use

- Indoor: Standard paper labels work well

- Outdoor: Choose UV-resistant vinyl or weatherproof materials

- Application Surface

- Smooth surfaces: Standard adhesives

- Rough surfaces: Strong adhesive options

- Curved surfaces: Flexible materials

- Duration of Use

- Temporary: Removable adhesives

- Permanent: Strong permanent adhesives

- Long-term outdoor: Laminated materials

What maintenance do sticker printers require?

Regular maintenance ensures optimal performance:

- Daily Tasks

- Clean external surfaces

- Check paper paths

- Remove debris

- Weekly Tasks

- Clean printheads

- Inspect rollers

- Check alignment

- Monthly Tasks

- Deep clean internal components

- Update software

- Calibrate settings

Future Trends in Sticker Printing

Emerging Technologies

- Smart Label Integration

- NFC-enabled labels

- QR code integration

- Track-and-trace capabilities

- Interactive packaging solutions

- Eco-Friendly Solutions

- Biodegradable materials

- Recycled content options

- Energy-efficient printing

- Waste reduction features

- Advanced Connectivity

- Cloud-based printing

- Mobile integration

- Remote management

- Automated workflows

Industry Developments

- Market Growth

- Expanding e-commerce needs

- Increasing customization demands

- Growing small business adoption

- New application areas

- Technical Advancements

- Higher print resolutions

- Faster printing speeds

- Improved durability

- Enhanced color accuracy

Conclusion

Choosing the right sticker printer is a crucial decision that can significantly impact your business operations and bottom line. With the rapidly evolving technology and growing market demands, investing in quality printing solutions has become more important than ever.

Key Takeaways

- Consider your specific printing needs and volume requirements

- Factor in both initial and long-term costs

- Choose technology that matches your application

- Plan for future growth and adaptability

- Prioritize reliability and support

Why Choose Eden Printer for Your Sticker Printing Needs?

- ✓ 16 years of specialized experience in thermal printing

- ✓ Comprehensive range of reliable solutions

- ✓ Expert technical support and guidance

- ✓ Flexible ordering options

- ✓ Competitive pricing without compromising quality

Ready to elevate your printing capabilities?Get Expert ConsultationView Product Catalog

Contact our experts today to find the perfect sticker printer solution for your specific needs. Let us help you make an informed decision that will benefit your business for years to come.