Thermal printers are essential tools across industries, providing reliable, high-quality prints. However, like any equipment, they require regular maintenance to ensure peak performance. In this guide, we’ll explore why thermal printer maintenance is crucial and provide troubleshooting tips for common issues.

Why Maintenance Matters

Regular maintenance is vital to the longevity and efficiency of your thermal printer. Without proper care, issues like poor print quality, paper jams, and premature printer failure can arise. Here’s why consistent maintenance is essential:

- Print Quality: Regular cleaning ensures your prints remain sharp and legible. Dust, debris, and residue can accumulate on the printhead, impacting print clarity.

- Preventing Paper Jams: A well-maintained printer is less prone to paper jams. Cleaning rollers and inspecting sensors can prevent paper misfeeds.

- Extending Printer Lifespan: A well-maintained thermal printer can last for years, providing better value and a stronger return on investment.

Essential Maintenance Tips

Follow these simple maintenance steps to keep your thermal printer in optimal working condition:

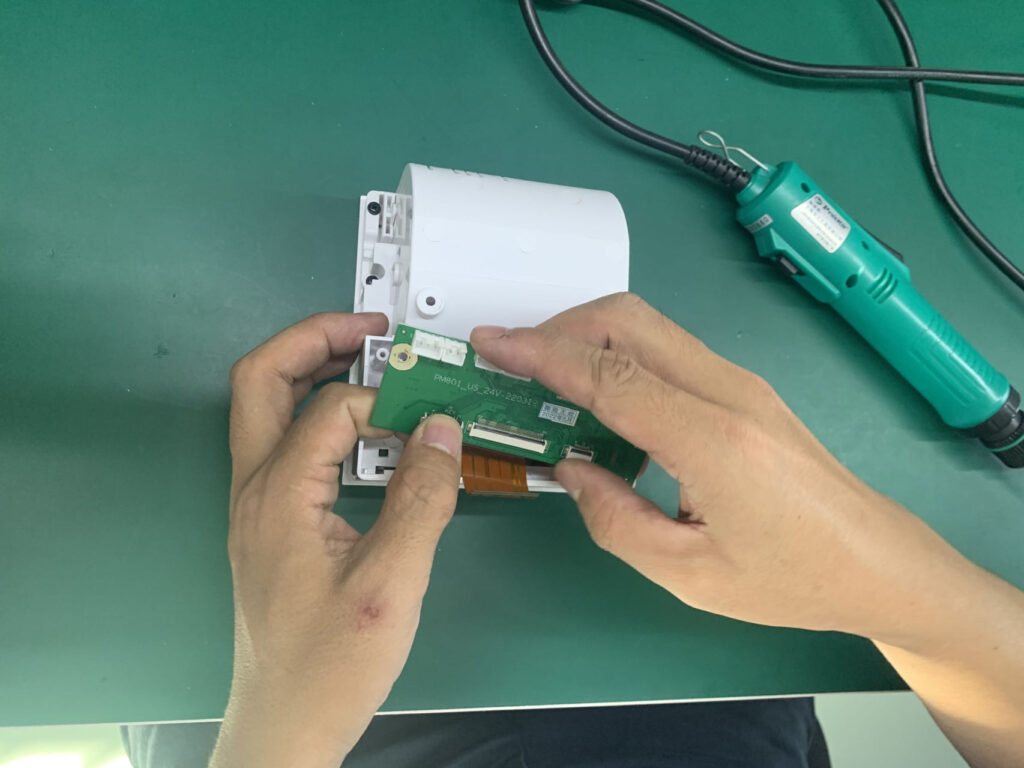

- Clean the Printhead: The printhead is the most critical component of a thermal printer. Clean it regularly using a soft, lint-free cloth and isopropyl alcohol. Gently wipe the printhead to remove dust and residue without damaging it.

- Inspect Rollers and Sensors: Periodically check the rollers for wear and tear or debris. Clean them carefully with a cloth. Similarly, inspect the sensors and remove any blockages or obstructions to ensure smooth operation.

- Replace Consumables: Keep an eye on the condition of labels, ribbons, and thermal paper. Worn-out or low-quality consumables can lead to print issues and compromise the quality of your outputs.

- Keep the Printer Exterior Clean: Wipe down the exterior of your printer to prevent dust accumulation. Avoid using abrasive cleaning materials that could scratch the printer’s surface or damage components.

Troubleshooting Common Issues

Despite regular maintenance, thermal printers can sometimes face operational issues. Here are solutions for some of the most common problems:

- Poor Print Quality: If your prints are faint, blurry, or have gaps, this could be due to a dirty printhead. Clean the printhead thoroughly with isopropyl alcohol and a soft cloth.

- Paper Jams: Frequent paper jams may indicate a problem with the rollers or paper alignment. Clean the rollers, check for obstructions, and ensure the paper is correctly loaded.

- Label Misalignment: If your labels are misaligned, adjust the alignment settings in your printer’s software. Ensure that the printer’s label detection sensors are working properly.

- Printer Not Responding: If your printer is unresponsive, check the power connections, reset the printer, and confirm it’s properly connected to your computer or network.

- Error Lights: Error lights on your printer indicate specific issues. Refer to the printer’s manual for guidance on interpreting error codes and resolving them.

Conclusion

Proper maintenance and troubleshooting are key to keeping your thermal printer in top condition, ensuring it delivers high-quality prints and lasts longer. Regular cleaning of the printhead, inspecting rollers and sensors, and replacing consumables will help maintain optimal printer performance. By promptly addressing common issues, you’ll minimize downtime and keep your printer running smoothly.

If issues persist or if you need technical support, it’s recommended to consult the printer’s manufacturer or a qualified technician for professional assistance.

2 Responses

The clarity and insight you offer here have the power to change the way we see the world around us.

Thank you so much for your thoughtful words!